EGO

After the implementation of the General food law in the EU a modification of many German regulations became necessary.

The German legislation differs from the legislations of other European countries because of the federal system. To a bigger part the execution of EU or national regulations is incumbent upon the federal states. Germany consists of 16 federal states and as a result it could have 16 different interpretations of one EU regulation. This situation could be really difficult for small and medium sized enterprises, because of different conditions of competition.

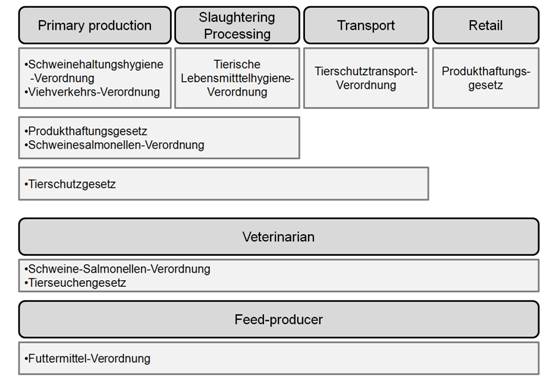

The following figure 1 gives an overview of German regulations.

Figure1: Outline of important German regulations influencing several production stages

The Schweinehaltungshygiene-Verordnung manages a veterinary support of the pig producer and of finishing farms. This obligate veterinarian support has the objective to improve the health status as well as to inspect the pigs clinically, especially on signals of epidemics. Besides the veterinary farm checks cleaning and disinfection, internal self-checks as well as demands for reproduction are included in the Schweinehaltungshygiene-Verordnung. See the detailed regulation.

The hygienic conditions for all animal transfers and the clear identification of animals are regulated in the Viehverkehrsverordnung. Every pig farmer has to report the receipt of pigs within seven days to the national database HIT (German livestock information system).

See the detailed regulation.

See the detailed Tierische Lebensmittel.

See the detailed Produkthaftungsgesetz.

A precondition for the attendance to the QS-system is the salmonella monitoring of hogs. Since March 2007 this salmonella monitoring also became obligatory by law through the introduction of the Schweine-Salmonellen-Verordnung. All finishing farms with a herd size more than 100 (more than 250 hogs per year) have to detect their salmonella status within one year for the first time in March 2008. An amount of the demanded samples per farm results from the number of slaughtered pigs. Table 1 shows the official sampling scheme.

Table1: Salmonella sampling scheme (according to Schweine-Salmonellen-Verordnung 2007)

Number of pigs, which are expected to be delivered for slaughtering |

Number of the pigs, which should be tested |

< 45 |

26 |

45 - 100 |

38 |

101 - 200 |

47 |

> 200 |

60 |

All samples are sent to the animal health service to be analysed. Farmers have to collect their results, to calculate the percentage of the positive salmonella samples in average of the past twelve months and to save them for at least three years. On basis of these average values they quarterly have to detect and document the salmonella antibody status of their livestock according to table 2. If the farmers participate in the QS system these calculations are done by the QS coordinator and the results are saved in the official QS database.

Table 2: Evaluation of the results (according to D 2007a)

Salmonella-risk of the live stock |

Category |

Positive results of the sample |

low |

I |

bis 20 |

medium |

II |

> 20 bis 40 |

high |

III |

> 40 |

Farms, which are classified in the third category, are obligated to inform the public veterinary agency in written form. In cooperation with the farms veterinarian they have to identify the salmonella entries and implement activities for the reduction of the salmonella prevalence.

See the detailed Schweinesalmonellen-Verordnung.

The Tierseuchengesetz rules the proceeding and the responsibilities within the scope of research on animal epidemics as well as the regulations about the intra-community animal transport. Additionally, it deals with the import, export, the obligation to disclose and inform as well as the monitoring executed by veterinarians. This order influences the whole production chain. However, the focus lies on primary production.

See the detailed Tierseuchen-Gesetz.

See the detailed Futtermittel-Verordnung.

National quality management system Qualität und Sicherheit (QS)

In recent years German pork production has become more focused on quality, which is assured by the private quality system QS. This system was first implemented across all stages of production as a consequence of the BSE crisis and other crises in the food sector in 2001. Comparatively high pork production costs and competition with the national quality systems of other EU member states supported the development of this national quality standard. In 2006 about 90% of the pigs in Germany were slaughtered under the QS system, and that percentage continues to grow.

The abbreviation QS stands for quality and assurance. The main objectives of this national quality management scheme are inter-enterprise quality assurance, transparency of the production processes in the entire production chain as well as strengthening of consumer trust in food. A series of QS compendiums exist for the different production stages of the pork chain: feed monitoring, animal production, salmonella monitoring, slaughtering and deboning and processing.

A three-stage control system monitors participants’ compliance with the QS requirements. Each participating enterprise has to document all of its activities as part of the self-control system. At regular intervals, neutral certification agencies check their compliance with the QS criteria. In a third step, the certification agencies themselves are controlled.

End of 5 Level 2 Eichenhof

5 Level 2 Eichenhof

Quality management in the Eichenhof chain:

The quality management is defined by a common quality policy. End products, predominantly fresh meat and to some extent also processed meat products, are marketed via the meat brand program. The controlled pork chain, from breeding to consumer, is part of the marketing concept of this program. All procedures during and along the pork production are contractually and transparently arranged and belong to the common quality strategy of the pork chain.

The criteria for the quality and producer guidelines are the following:

- Uniform production and hygiene guidelines

- Integrated agricultural enterprises and an abattoir with affiliated processing

- Homogeneous finisher groups with uniform weights and health status

- Integrated veterinarian support system

- Software-supported operational data collection and data exchange (complete traceability)

- Salmonella monitoring

- max. 80 km distance between abattoir and finishing units

- Central feed buying by defined feed producers; routine feed analyses

Table 1 shows that this partially integrated system with an own meat brand program is based on the German QS standard (Quality and Safety). All stakeholders of the chain are certificated. The intersectoral IFS standard exists in the abattoir with affiliated processing of the cooperative. Due to the strict requirements of the meat brand program, veterinarians are part of the integrated veterinary support system via general agreements (framework agreements). The official controls along the chain correspond to legal requirements. Following table 1 exemplarily shows the use of quality management tools.

Table 1: Quality management in the Eichenhof chain

Stakeholders |

Quality programs / standards |

Plan |

Do |

Check |

Act |

Inspection and audit tasks of public authorities |

|

Supplier / Service |

Veterinarian

|

QS,Eichenhof |

2 routine Audits p.a. (1 with EGO advisor) |

Implementation of the Health-Audits (>1/year) |

Conformance control |

Consultation to the preservation or improvement of the health-status farms |

Random check-up of compliance to regulations (10 % of the farms in a district/year) |

Feed producer |

DIN EN ISO 9001, QS, GMP+, Eichenhof |

HACCP concept, |

Tracking and tracing of raw materials, monitoring of residues |

Internal and external QS audits |

Supply chain management, reclamation management, retention samples, |

Risk-oriented supervision (control) by the public veterinarian |

|

Carrier |

QS, Eichenhof |

Self-control according to QS guidelines |

Tachograph, |

Self-control system according to QS guidelines |

Documentation of transport time and conditions |

Official audits, accreditation of carriers |

|

Supply Chain |

Breeding |

QS |

Self-control according to QS guidelines |

Securing the traceability of pig and semen deliveries, |

Internal and external QS audits |

Supply chain management, reclamation management, retention samples, |

Random audits of farms by the public veterinarian |

Multiplying |

QS |

Self-control according to QS guidelines |

Documentation, |

Internal and external QS audits |

Central supply chain management, |

Random audits of farms by the public veterinarian |

|

Piglet production/ finishing |

QS, Eichenhof |

Self-control according to QS guidelines |

Documentation, |

Internal and external QS audits |

Central supply chain management, |

Random audits of farms by the public veterinarian |

|

Abattoir |

QS, IFS, technical inspection authority, Eichenhof |

Self-control according to QS guidelines, HACCP concept, |

Control of in- and outgoing goods, process controls |

Internal and external QS as well as IFS audits, technical inspection authority |

Central supply chain management, |

Inspection of finisher and meat during slaughter by public veterinarian authority |

|

Processor |

QS, IFS, Eichenhof |

Self-control according to QS guidelines, HACCP concept, own QM system |

Control of in- and outgoing goods, process controls |

Internal and external QS as well as IFS audits, technical inspection authority |

Supply chain management, |

Official controls (food control authority) random and risk oriented plant audits |

|

Customer |

Retail / butcheries |

QS and TÜV-Vitacert (except retail), Eichenhof |

QS, HACCP concept |

Control of in- and outgoing goods, process controls |

Internal and external QS audits, TÜV audits, product audits |

Supply chain management, |

Public controls, risk-oriented food control, monitoring |