Potential Fast and Non-destructive Methods

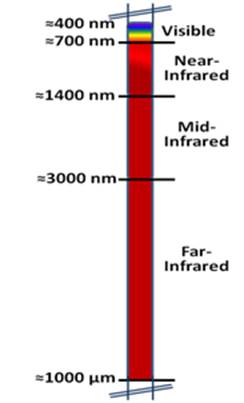

- Near Infrared Spectroscopy: NIRS involves the region of the electro-magnetic spectrum (Fig. VI-1) from about 700 to 2500 to 3000 nm; some instruments can also measure the visible portion of the spectrum (400 to 700 nm). NIRS measures the difference between the composition of the instrument's light source and the composition of the light after it is exposed to a sample. The resulting spectrum of the sample is then evaluated. In general, the sample's molecular bonds absorb specific wavelengths (energy) for their vibrations and overtones. NIRS patterns have been recognized for many years, as William Herschel reported their fundamental aspects in 1800.

Figure VI-1. Sketch approximating the NIRS electro-magnetic spectrum.

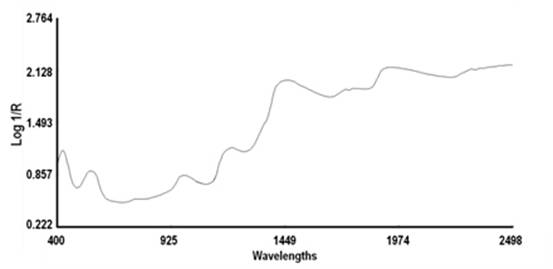

Absorption spectra in the NRI region often appear featureless (Fig. VI-2) because they are composed of broad and overlapping overtones or combinations of overtones. Specialized computer software programs featuring fundamental absorption controllers that can help delineate relationships of band patterns and reference parameters. In contrast, the absorption bands in the mid-infrared region are distinctly sharp.

Figure VI-2. NIRS spectrum of a pork sample.

In the late 1950s, Karl H. Norris, at the U.S. Department of Agriculture, pioneered computer analysis of the NIRS region to help resolve the complicated nature of the spectra. The first commercial application of NIRS was for quantifying protein in wheat by the Canadian Grain Commission.

NIRS technology involves exposing samples to known qualities of light. The reflected light is measured and converted into units of absorbed light, which reflects the chemical properties of the sample's composition. The goal is to find absorption patterns that are highly related to chemo-metric determinations of the sample's inherit chemical and/or physical properties so that prediction equations can be developed. The complex absorption bands in the NIR region can reveal information pertaining to meat quality, WHC, and numerous other traits.

Figure VI-3. NIRS unit scanning pork longissimus.

The qualitative and quantitative chemistry of meat has become and will continue to become more detailed and sophisticated. The calculating power of computers enables testing of many more complex tests for relationships to the sample's NIRS absorption band pattern and behaviour. For these tests to be successful it is important to create datasets which contain large variations in the reference trait of interest. With all "natural" variation included, the chemo metric comparisons utilizing computer software can determine if significant relationships exist between measured reference parameters and the complex NIRS absorption bands.

Calibration for the NIRS methods has been a major hurdle. In fact, nearly every individual product needs its own calibration, and this requires considerable attention to detail, a large number of observations (sometimes into the thousands), and validation of prediction equations. Once established, NIRS data can often provide data on many different chemical, physical, and sensory properties of meat, which would be extremely useful, making NIRS a powerful tool for automated, higher volume systems that need continuous feedback.

To date, most studies go to great lengths to control as many factors as possible that can affect WHC: genetic, live animal practices, animal age, slaughter times and conditions, chilling regimens, all post-mortem times, temperatures, packaging regimens, and sample preparation, among others. Then, some form of treatment is superimposed to create variation in WHC. Without the variation, obtaining correlations with any strength would be difficult. One or more measures of WHC are studied and then compared with the predicted output. Obviously, if the standard reference methods used to measure inherent WHC are not accurate and precise, then the NIRS relationships are in doubt.

Often, the longissimus muscle is used for NIRS predictions, but other muscles, especially those in the deeper portions of carcasses have different chill, pH, and protein denaturation profiles than the longissimus. Loin quality generally reflects total carcass quality. However these other muscle areas contribute a greater mass contribution to carcass yields than the longissimus muscle, they merit investigation because they will likely need different prediction equations.

Figure VI-4. Calibration of actual drip values vs. NIRS predicted values.

Correlations with cross-validation studies often range from about 0.25 to 0.68, with some studies obtaining correlations in the mid to upper 0.70's. If predictions equations for WHC can be validated with high accuracy using independent data sets, successful industry applications could be tested. However, additional refinement is needed because these correlations only account for about 50% of the variation in WHC. Nevertheless, NIRS measurements can sort meat into WHC categories of high WHC (less than 2 % losses) or low WHC (more than 4 % losses).

Although these correlations are encouraging (Fig. VI-4), sample procurement and handling as well as treatment of the data and the NIRS scans need further refinement to improve the overall prediction accuracy. NIRS technology is more highly developed for grain applications. For NIRS calibration for grain, Williams (2007) describes the relationship between strength of correlations and ability to control variables as r-values: ≥ 0.99 = excellent; ≥ 0.96 - 0.98 = useable in most applications; ≥0.91 to 0.95 = useable with caution; ≥0.81 to 0.90 = Okay for screening and approximate calibrations; ≥0.71 - 0.80 = Ok for rough screening; ≥0.51 - 0.70 = more research needed. Clearly, NIRS technologies for meat do not yet meet these standards.

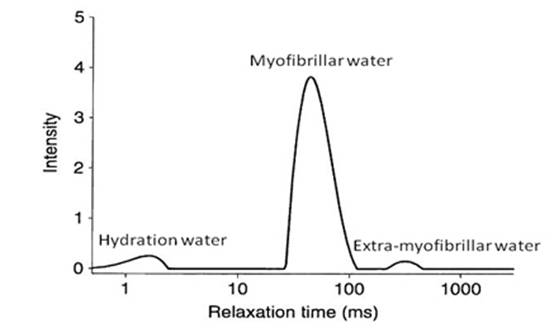

- Nuclear Magnetic Resonance (NMR): NMR works on the principle of determining the electronic spin of a nucleus and low-field NMR T2 relaxometry, which is used for determining WHC. The relaxometry is based on differences in the relaxation time of protons depending on their environment. The signals have been ascribed to hydration water closely associated to macromolecules, myofibrillar water and extra-myofribrillar water (Fig. VI-5). NMR could provide reasonably rapid, non-invasive analysis of the distribution and mobility of water in meat, and at the experimental level, the method correlates well to established methods for determining WHC.

The NMR technology could be at-the-line and possibly even on-line at slaughter plants, but smaller, faster, more economical NMR-equipment must be developed before its potential can be exploited by industrial meat operations.

Figure VI-5. Distributed proton T2 relaxation times measured in a pork sample at 25 C. Three populations at approximately 1-3 ms, 40-80 ms and 200-400 ms are detected (based on Bertram and Andersen, 2007).

As with NIRS studies, some treatment or combination of treatments must be imposed on pigs to create different responses in their muscle metabolism. Correlations ranging from 0.1 to 0.69 have been reported for various meat quality traits, WHC, and plasma metabolites. Even though metabolite analyses accounted for less than 20% of the variation in WHC, authors were encouraged about using the NMR protocol with some modification for the early prediction of meat quality.

- Biomarkers: Logic suggests that measures of genetic and environmental traits either by themselves or in combination, could be used to predict meat WHC. Biomarkers are genes or gene products formed via interactions between an animal's genes and its production and ante-mortem environments. One limitation of biomarkers is that they represent only a portion (mainly before slaughter) of the factors that affect WHC, and finding biomarkers that relate to the complexity and variability of the post-mortem environment is a challenge. However, since meat quality is the result of interactions of both ante-mortem and post-mortem conditions, this methodological approach could create new ways to evaluate and improve WHC.

NMR, when combined with other techniques, could identify biomarkers that could differentiate meat properties associated with WHC. The NMR technique suitable for this approach is high-field NMR (Fig. VI-6) where metabolites are identified (metabonomics).

Figure VI-6. High-field NMR scan of metabolites with potential as biomarkers.

Presently, the search for biomarkers and the validation of these markers is receiving considerable attention. Sophisticated techniques are being used for identifying changes in genes (genomics), gene-transcripts (transcriptomics), proteins (proteomics), and metabolites (metabonomics), which may correlate with meat quality parameters, including WHC. All of these are potential biomarkers, but in reality, several biomarkers will need to be combined to obtain sufficiently strong correlations to WHC. The advantage of these "omics" techniques is that they are exploratory; a very large number of biological mixtures at different levels are analyzed to establish a huge base for the correlation analysis. Finding biomarkers often results from one technology and within one genetic and production scheme, so additional work would need to verify that they work with other methodologies and genotypes.

Once appropriate correlations are obtained, other more simple, robust, and rapid analysis approaches, such as antibody-based systems, could be developed using identified biomarkers. Meat industry personnel can then use optimized assays to help adjust genetic lines, animal production systems, and meat industry practices that improve WHC in industrial settings.