Compartments for Holding Water in Meat

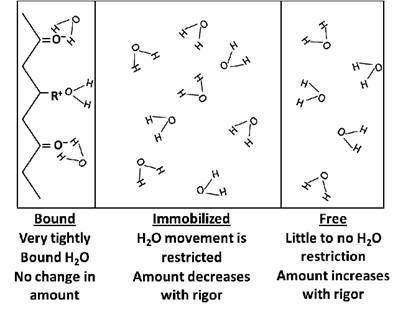

The macro and micro structure of muscle has several compartments where water may be held. In general, research has categorized water as being either "free", "immobilized", or "bound". These three categories vary considerably in the "tightness" and the "degree" of immobilization of the water. In reality, some water is just physically trapped in spaces and can readily be lost as drip or purge. Some water is restricted in various degrees but can still be held or lost, and a small portion is very strongly bound that cannot be lost from meat.

Figure I-4. Compartments or forms of water in meat. Water would be immobilized in meat due to the positively charged hydrogen being attracted to the negatively charged areas of proteins, whereas the negative charge of the oxygen would be attracted to positive charges of the protein.

- "Bound Water": This compartment of water is the smallest (1-2%) and the strongest of the three (Fig. I-4). This portion of the total moisture is very tightly associated with meat proteins and is nearly impossible to remove from meat. For all practical purposes, meat processing has little effect on this compartment of water.

- "Immobilized Water": Up to 80% of the water in fresh meat is immobilized (Fig. I-4). Water in this compartment ranges from moderate electronic associations between water and the muscle proteins to very weak associations as the water molecules increase in distance from the positive and negative charges on the proteins. Immobilized water has weaker associations with proteins and other cellular components than bound water. Immobilized water is subject to either being lost or it may be moved into the "free" water category. For meat processors, the more water that is immobilized, the greater the WHC.

- "Free Water": As the name implies, water in this category is subject to being lost (Fig. I-4). The major restrictions for this water are the cell membranes and capillary restrictions related to the width of the spaces between the interfibrillar strands of muscle proteins (see Fig. II-2). Any combination of forces that damage muscle cellular integrity will help release free water from meat. However, with proper processing, some free water can be shifted into the immobilized compartment, which is more likely to be retained. Processing that reduces the amount of protein denaturation during the conversion of muscle to meat and factors that increase muscle pH, the electrostatic repulsion of the proteins, increasing sarcomere length, minimizing damage of the muscle structure, maintaining low storage temperatures, and avoiding freezing pre-rigor meat, will help maintain water in the immobilized compartment and minimize the movement of water into the free compartment.